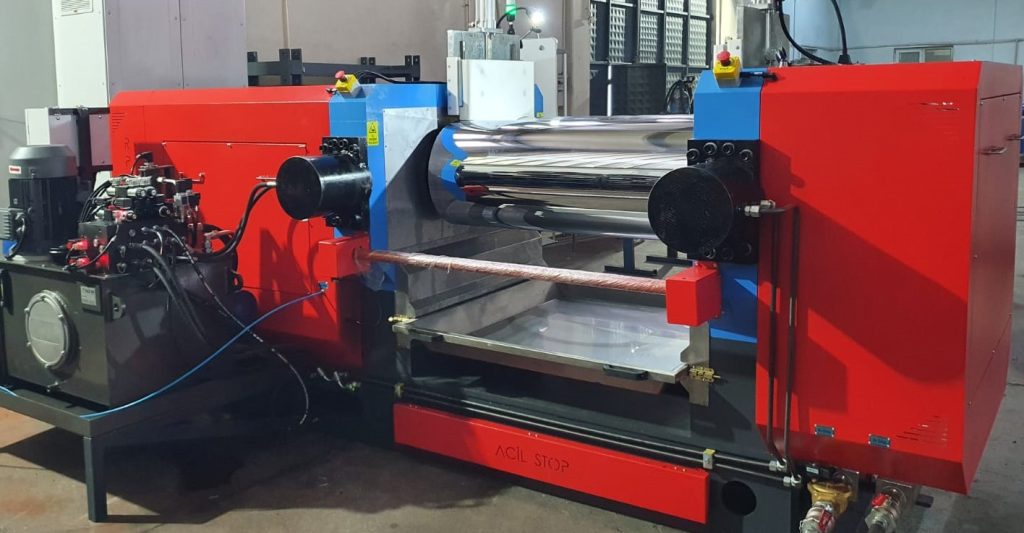

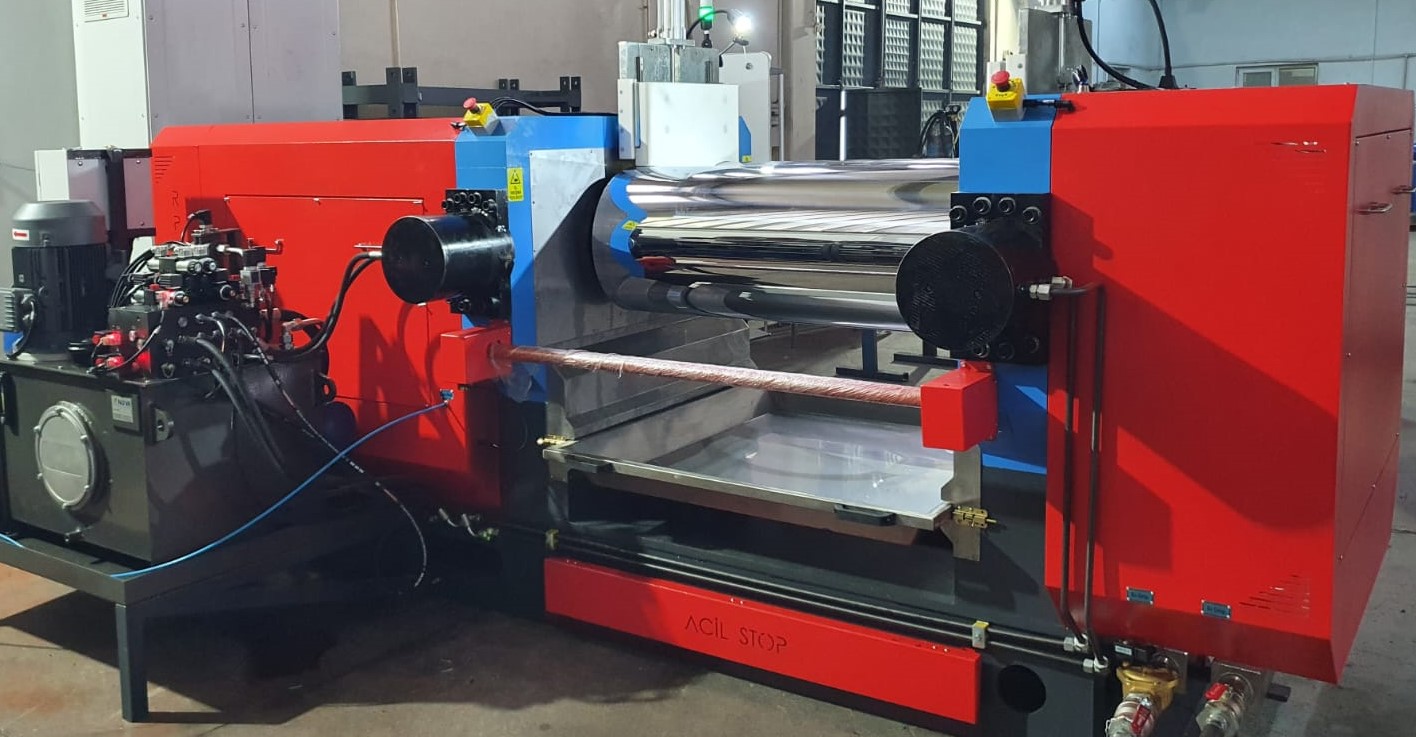

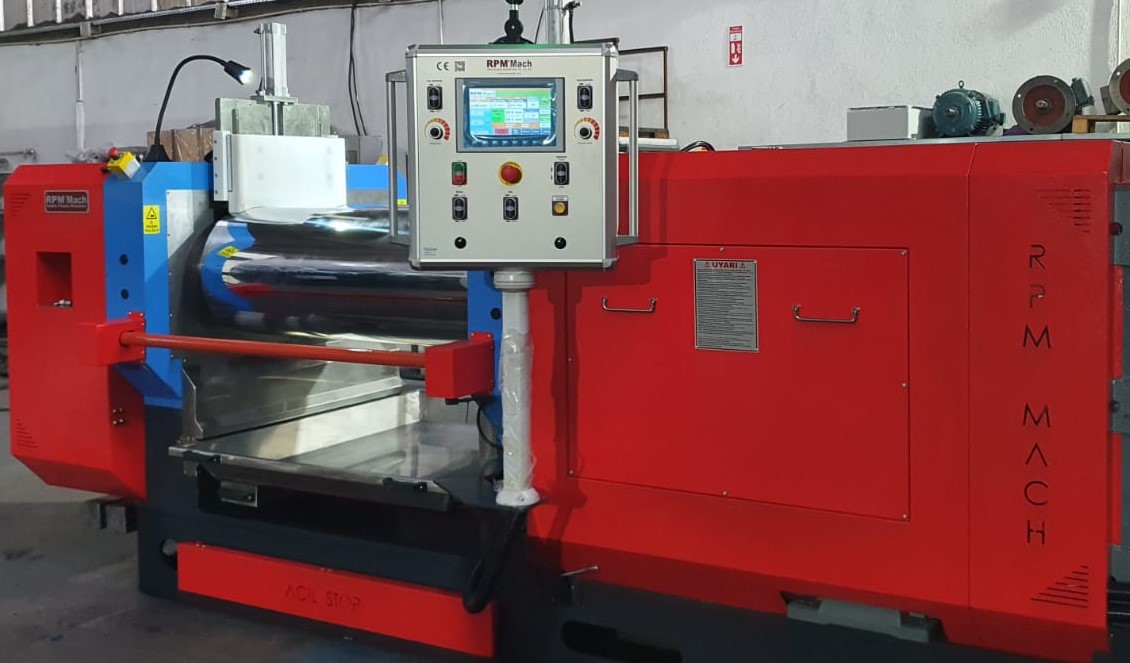

Rubber Open MIxIng MIll

Designed and continuously developed by RPMMACH, our Rubber Open Mixing Mills are at the forefront of innovation. Our models are recognized as the most advanced, technologically superior, safest, and most ergonomic designs in their segment worldwide.

RPMMACH is dedicated to manufacturing rubber compound machines with the highest standards of work and worker safety. Our commitment to safety is matched by our ongoing advanced R&D efforts, ensuring innovation across all our rubber processing machines.

Innovative Rubber Compounding Machines

Our rubber compounding machines are designed for ease of use and efficient processing. They come equipped with numerous important and useful options and functions that set them apart from others in the market. These features have now become standard across all our models.

Advanced Safety And Efficiency Features

- Work and Worker Safety: Compliant with DIN1417 2015CE Standards.

- Process Ease: Every detail meticulously considered for optimal process efficiency.

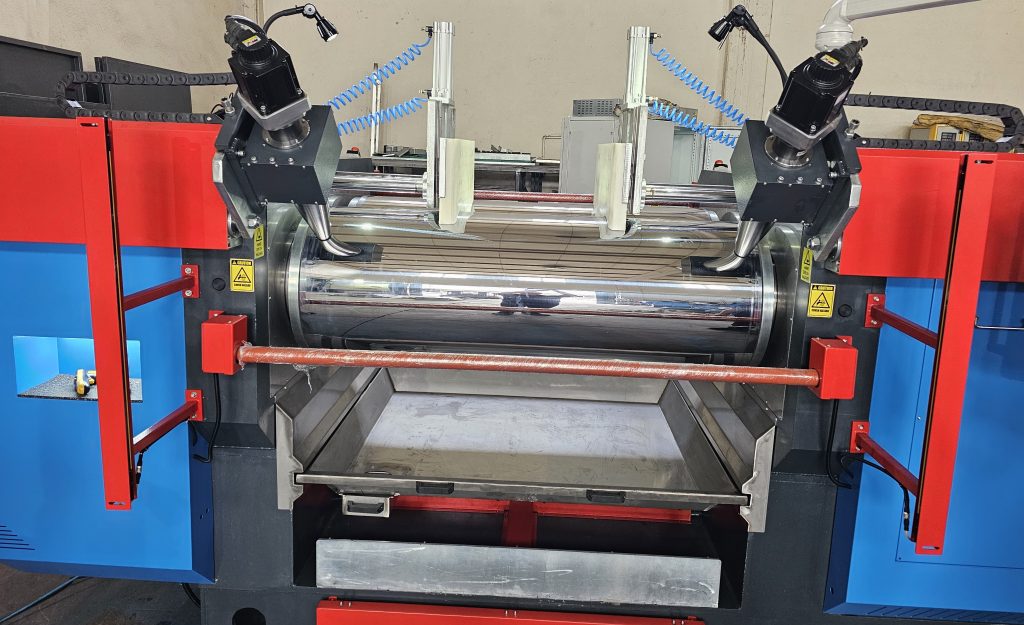

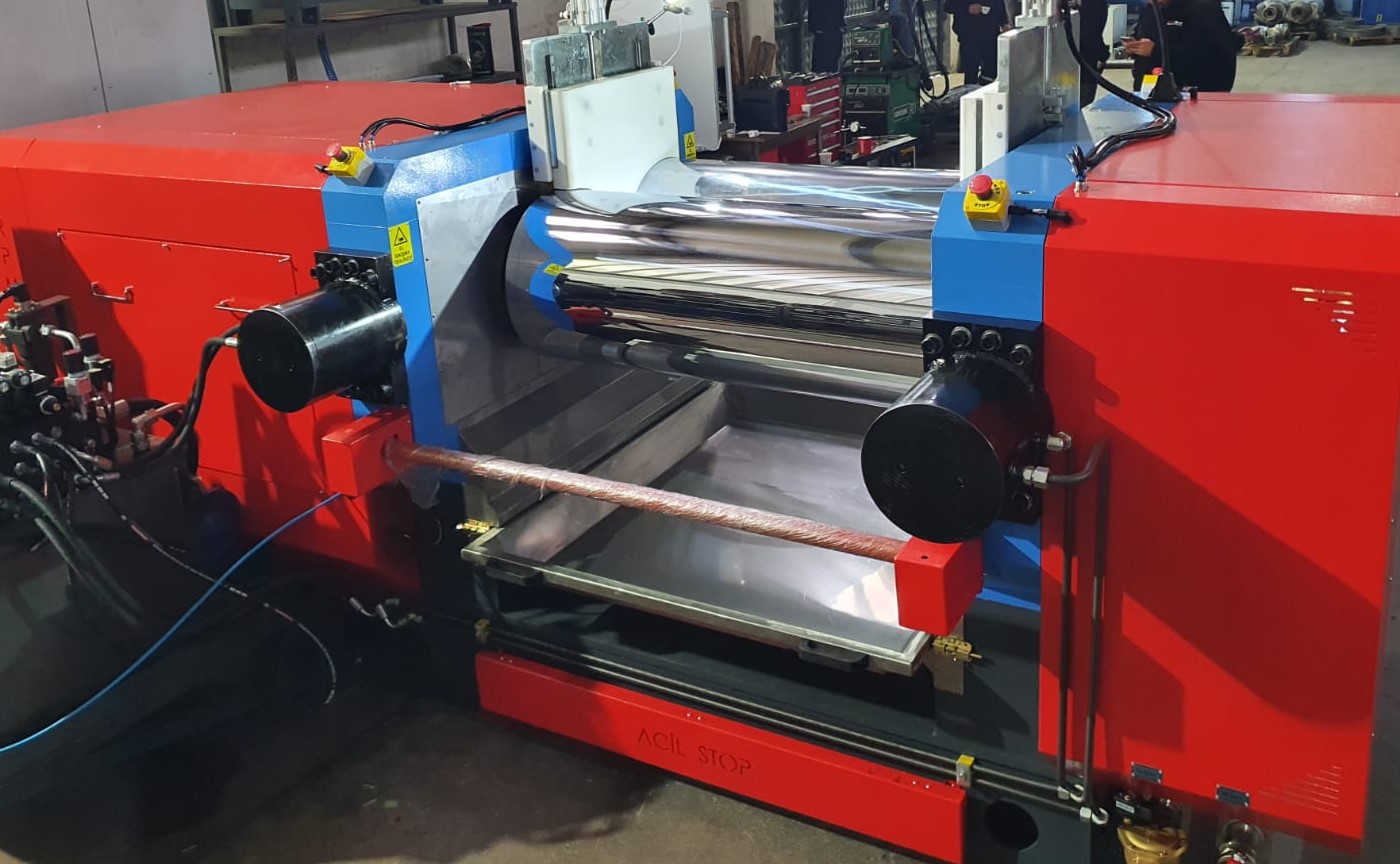

- Cooling System: Peripheral (drilled) roller surface cooling system.

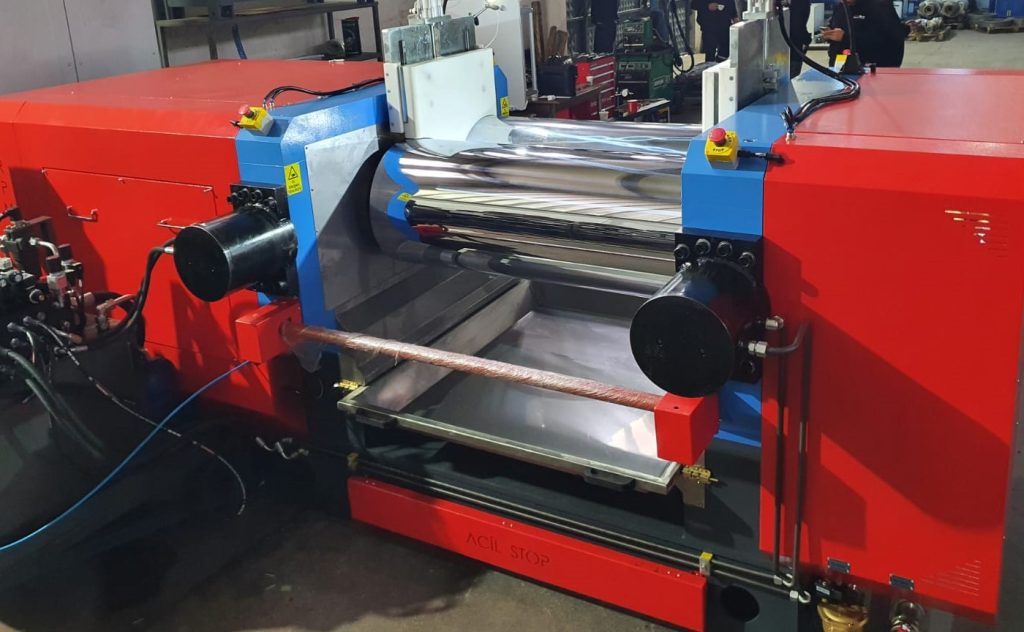

- Enhanced Control: Double motor, double reducer, double inverter spindle speed control, and instant friction adjustment.

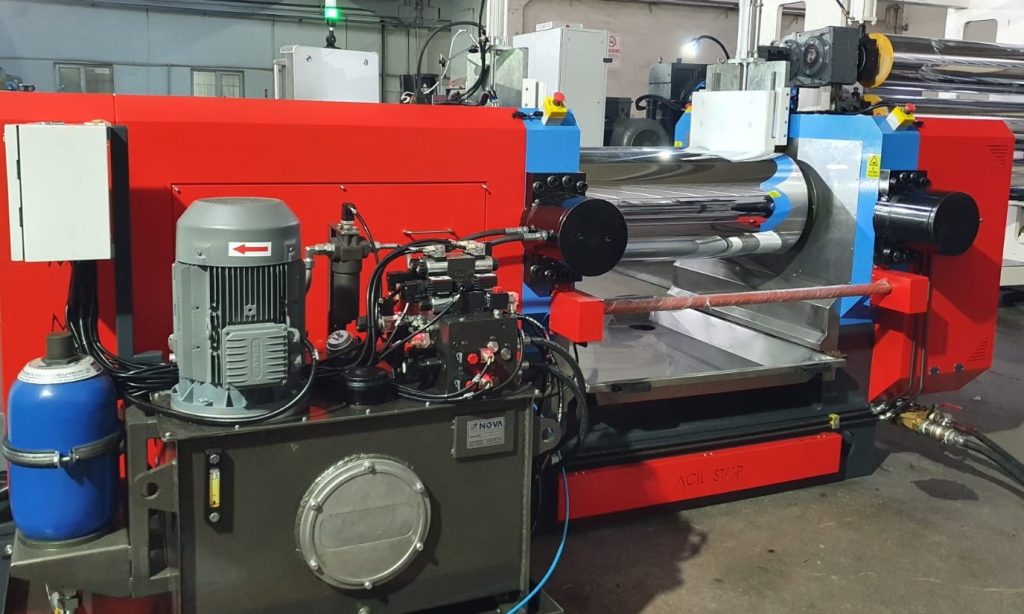

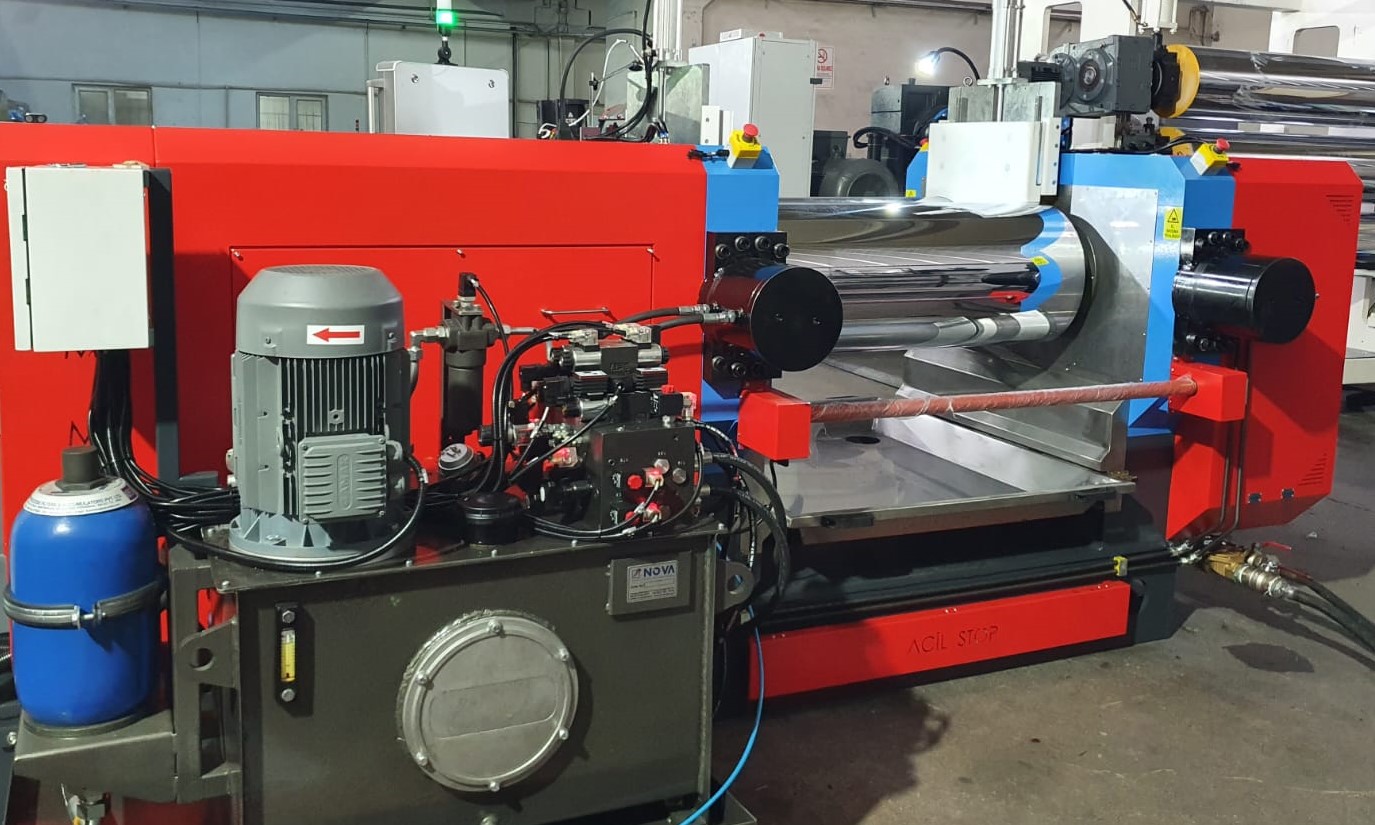

- Stronger Construction: Shaft material made from forged steel AISI4140 (1.7227, DIN 42CrMoS4).

Efficient Roller Cooling System

Our compounding machines feature a roller cooling system using the “DRILLED” Peripheral method. This system employs a pressurized water cycle close to the cylinder surface, ensuring efficient cooling. This advanced cooling system is a standard option across all our open mixing mill models.

Our rubber open mixing mills come equipped with PA66 BARRIERS (STOCK GUIDES) that can move along the rollers using a hydraulic system. This standard feature in all our models direct the compound also allowing for efficient mixing even with smaller quantities.

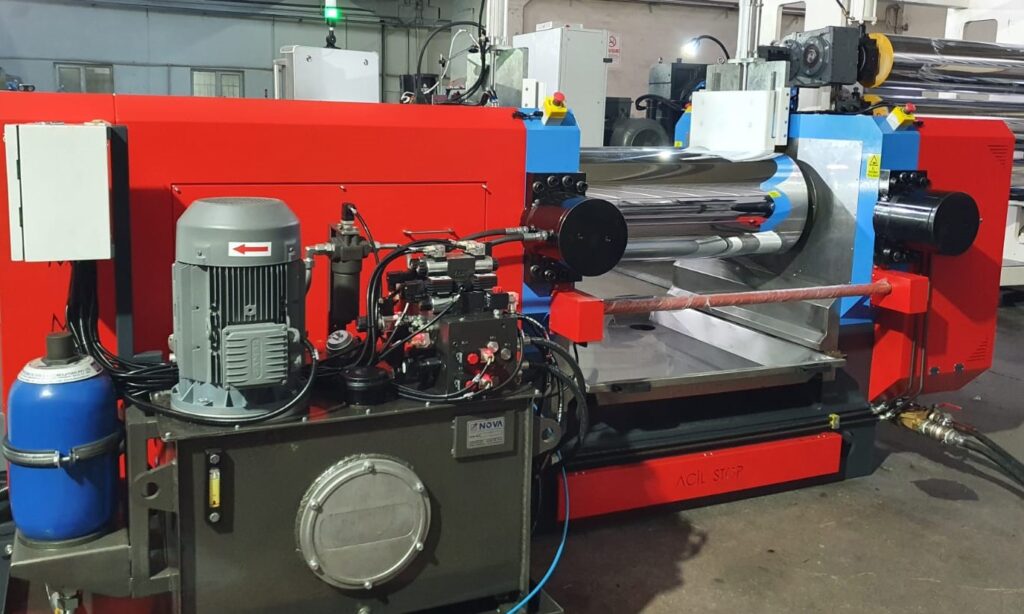

Hydraulic System For Gap Adjustment

Our advanced hydraulic system ensures precise back-and-forth movement of the rollers, adjusting the gap distance with remarkable speed and efficiency. Compared to motorized systems, our hydraulic solution is more powerful, safer, longer lasting, and significantly faster.

One of the standout features of our hydraulic system is its ability to adjust cylinder gaps even while in operation, regardless of any compound present on the cylinder. This capability ensures continuous, uninterrupted performance.

Additionally, this feature allows for automatic adjustment of cylinder gaps via the control panel, providing seamless and user-friendly operation.

Advanced Mixing And Homogenization Systems

Our STOCK-BLENDER option, which significantly enhances the quality of mixing and homogenization, is designed for ease of operation. The hydraulic system that drives compound movement features adjustable speed, ensuring long-lasting durability and reliability.

As an alternative to the Stock-Blender, we offer the [CROSS BLENDER] homogeneous compound mixing system. This innovative system, patented by RPMMACH, allows for the homogeneous and equal mixing of certain polymers without direct contact.

All our models come standard with a shaft-transferred reducer cylinder connection and double motors. The advantages of using double motors include:

- Reduced difficulty during mixing.

- Minimized metal fatigue.

- Adjustable and proportional cylinder speeds and friction.

- Safe and easy adjustment of cylinder gaps up to 50 mm.

We also offer designs with special Hydromotor drive systems. The HAAGLUNDS-Rexroth brand Hydromotors, known for their power and reliability, are specially designed for our Open mixing mill in select projects.

Dough Shaft models are listed below according to their shaft dimensions:

- 180x450mm

- 250x500mm

- 300x700mm

- 360x900mm

- 400x1000mm

- 450x1200mm

- 550x1500mm

- 610x1800mm

- 660x2100mm

- 700x2500mm

- 750x2800mm

For more detailed technical information, please contact our company.